Improving Harvest Efficiency with Grain Bin Moisture Sensors and 1×12 Press Wheels

In the agricultural industry, efficiency and precision are critical to success. Farmers continuously seek innovative tools and technologies to improve their operations, enhance crop yields, and ensure the highest quality of produce. Two such innovations making waves are grain bin moisture sensors and the 1×12 press wheel. These tools are transforming the way farmers manage their crops, leading to more efficient and profitable farming practices.

The Importance of Moisture Management in Grain Storage

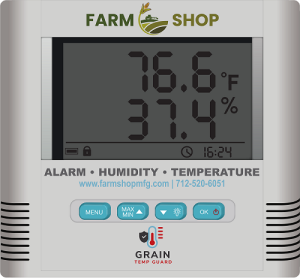

Managing moisture levels in grain storage is vital for preserving the quality and longevity of harvested crops. Excess moisture can lead to mold growth, spoilage, and significant financial losses. This is where grain bin moisture sensors come into play.

Grain bin moisture sensors are designed to provide real-time data on the moisture content within storage bins. By constantly monitoring and reporting moisture levels, these sensors help farmers take timely actions to maintain optimal conditions. The benefits of using grain bin moisture sensors include:

- Preventing Spoilage: By keeping track of moisture levels, farmers can take preventive measures to avoid spoilage, ensuring that the grain remains fresh and marketable.

- Improving Efficiency: With accurate moisture data, farmers can optimize the drying process, reducing energy consumption and operational costs.

- Enhancing Quality: Maintaining ideal moisture levels preserves the quality of the grain, resulting in higher-grade products that can fetch better prices in the market.

Innovations in Planting: The 1×12 Press Wheel

Alongside moisture management, planting efficiency is another critical aspect of successful farming. The 1×12 press wheel is an innovative tool designed to enhance the planting process. This press wheel is particularly effective in ensuring consistent seed-to-soil contact, which is essential for uniform germination and crop growth.

Key benefits of the 1×12 press wheel include:

- Enhanced Seed Placement: The 1×12 press wheel ensures that seeds are placed at a consistent depth, which is crucial for even germination and robust plant development.

- Reduced Soil Compaction: This wheel design minimizes soil compaction around the seed zone, promoting healthier root systems and better access to nutrients and water.

- Improved Crop Yields: By providing optimal conditions for seed germination and early growth, the 1×12 press wheel contributes to higher crop yields and improved overall farm productivity.

Integrating Technology for Better Results

Combining the use of grain bin moisture sensors and the 1×12 press wheel represents a holistic approach to modern farming. These technologies complement each other by addressing critical aspects of crop production and storage. Here’s how integrating these tools can benefit farmers:

- Comprehensive Crop Management: From planting to storage, these technologies provide a seamless flow of data and efficiency, ensuring that crops are managed optimally at every stage.

- Data-Driven Decisions: Farmers can leverage the data provided by grain bin moisture sensors and the performance improvements from the 1×12 press wheel to make informed decisions that enhance overall farm operations.

- Increased Profitability: By reducing losses due to spoilage and improving crop yields, these innovations can significantly boost a farm’s profitability.

Conclusion

In the rapidly evolving world of agriculture, adopting advanced technologies like grain bin moisture sensors and the 1×12 press wheel is essential for staying competitive and achieving sustainable success. These tools not only streamline farming operations but also contribute to higher quality and more profitable harvests. As farmers continue to embrace these innovations, brands like Farm Shop MFG LLC play a crucial role in providing reliable and effective solutions that drive the agricultural industry forward.