The Future of PCBs: Innovations Driving Smaller, Smarter Devices

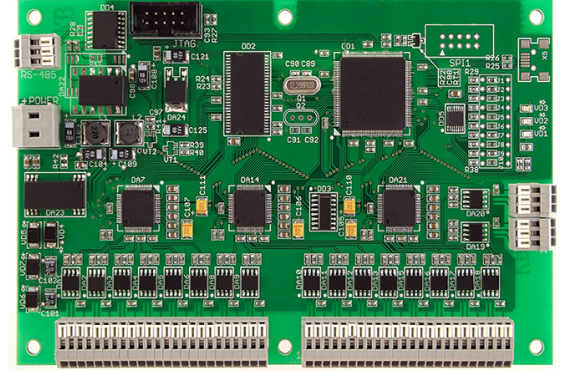

Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling the functionality of nearly every device we use daily, from smartphones to medical equipment. As technology continues to advance, so too does the need for smaller, more powerful, and more efficient PCBs. The future of PCBs is poised to usher in a new era of innovation, driven by the demand for smaller, smarter, and more compact devices.

As a leading Printed Circuit Board Supplier, understanding these innovations is critical for staying ahead in an increasingly competitive market. Let’s explore the key trends and technological advancements that are shaping the future of PCBs and enabling the development of next-generation electronic devices.

The Growing Demand for Smaller, Smarter Devices

The trend toward miniaturization in electronics has been ongoing for decades, but recent advancements in PCB design and manufacturing are pushing the limits even further. From the development of ultra-thin smartphones to the rise of wearable technology, the demand for smaller, smarter devices is at an all-time high.

For electronic devices to become smaller and smarter, the PCB must become more compact, efficient, and capable of handling increasingly complex functions. The future of PCBs will see a shift toward multi-functional, high-density designs that allow for smaller footprints while maintaining performance and reliability. These innovations are pushing the boundaries of what is possible in electronics, enabling engineers to develop devices with greater capabilities in a smaller form factor.

Advanced PCB Materials

One of the most significant innovations in PCB technology is the development of advanced materials. Traditional PCB materials like FR4 have been widely used for years, but they have limitations when it comes to supporting high-speed data transfer, thermal management, and miniaturization.

To meet the needs of modern electronics, Printed Circuit Board Suppliers are increasingly turning to advanced materials such as high-frequency laminates, flexible substrates, and high-density interconnects (HDI). These materials enable faster data transmission, better heat dissipation, and more compact designs. For instance, flexible PCBs allow for bending and conforming to unconventional shapes, making them ideal for wearable devices and other compact electronics.

The use of high-frequency laminates, which are often employed in 5G and IoT devices, allows for improved signal integrity and performance in high-speed applications. By utilizing these innovative materials, manufacturers can create smaller, more efficient PCBs that meet the rigorous demands of modern technology.

1. Flexible and Stretchable PCBs

Flexible PCBs are not a new concept, but their applications are expanding rapidly. These boards can bend, fold, and twist without damaging the internal circuitry, opening up possibilities for devices that need to conform to non-traditional shapes. For example, in wearable technology, flexible PCBs allow for the creation of ultra-thin, lightweight devices that can wrap around the body or be embedded into clothing or accessories.

Moreover, Printed Circuit Board Suppliers are also exploring stretchable PCBs, which can maintain electrical conductivity even when stretched or compressed. These innovations are particularly exciting for the development of advanced health monitoring devices and flexible displays, as they enable devices to be integrated seamlessly into everyday objects.

2. High-Density Interconnect (HDI) Technology

HDI technology is at the forefront of innovation in PCB design. HDI boards are characterized by high-density pads, finer traces, and more layers than traditional PCBs, allowing for more components to be packed into a smaller space. This is particularly important in the development of smartphones, tablets, and other consumer electronics, where space is at a premium, but performance cannot be compromised.

By using HDI technology, Printed Circuit Board Suppliers can create boards that support advanced features such as high-speed processing, wireless communication, and high-definition displays, all while keeping the size of the device to a minimum. As consumer demand for smaller, more powerful electronics grows, HDI technology will become an essential part of the PCB manufacturing process.

The Role of Automation in PCB Manufacturing

The drive toward smaller and smarter devices has also led to a significant shift in PCB manufacturing processes. Automation is playing a crucial role in improving the efficiency, precision, and speed of PCB production. Automated systems are capable of producing PCBs with minimal human intervention, ensuring high-quality standards while reducing production costs and lead times.

By automating the assembly and testing processes, Printed Circuit Board Suppliers can deliver high-quality, defect-free boards at a faster pace. This is especially important for industries where time-to-market is critical, such as consumer electronics, medical devices, and automotive applications.

The integration of automation and robotics into PCB manufacturing also opens up new possibilities for custom PCB designs, allowing for greater flexibility in terms of complexity, size, and shape. This means that manufacturers can more easily adapt to the specific needs of their clients and meet the increasing demand for tailored, high-performance PCBs.

3D Printing: A Game-Changer for PCB Prototyping

Another groundbreaking development in the PCB industry is the adoption of 3D printing for PCB prototyping. Traditional PCB prototyping methods often involve lengthy and costly processes, but 3D printing allows for rapid prototyping with minimal material waste. This technology enables designers to quickly create and test PCB prototypes, speeding up the development cycle and reducing costs.

3D printing also opens up new possibilities for PCB design, as it allows for the creation of more complex and intricate structures that would be difficult or impossible to achieve with traditional manufacturing methods. This level of design freedom can result in more efficient and innovative products, particularly in industries such as aerospace, medical devices, and robotics.

With 3D printing, designers can prototype multiple iterations of a PCB in a fraction of the time, allowing them to test different configurations and materials before moving to full-scale production. This technology is set to revolutionize the way PCBs are designed and manufactured, making it a key player in the future of the industry.

Miniaturization and Multi-Functional PCBs

As devices become smaller and more sophisticated, PCBs must also evolve to meet the demands of miniaturization. Multi-functional PCBs are one of the most exciting innovations driving the future of electronics. These boards combine several different functionalities into a single board, reducing the need for multiple separate PCBs within a device. For example, in consumer electronics, multi-functional PCBs can integrate power management, signal processing, and connectivity in a single compact design.

This trend toward multi-functional PCBs is enabling the development of smaller, more powerful devices that are capable of performing a wider range of tasks. As Printed Circuit Board Suppliers continue to innovate in this area, we can expect to see more advanced and integrated designs that push the boundaries of what’s possible in electronics.

Conclusion

The future of PCBs is brighter than ever, driven by innovations in materials, design, and manufacturing techniques. As demand for smaller, smarter, and more powerful devices continues to grow, Printed Circuit Board Suppliers are at the forefront of this transformation, developing cutting-edge technologies that are shaping the next generation of electronics.

If you’re interested in learning more about the latest PCB innovations or how these advancements can impact your product development, for detailed insights. To stay ahead in the world of electronics, be sure to click this link here now to explore how the future of PCBs can help drive your business forward.