How DTG printing works – Direct to Garments Printing

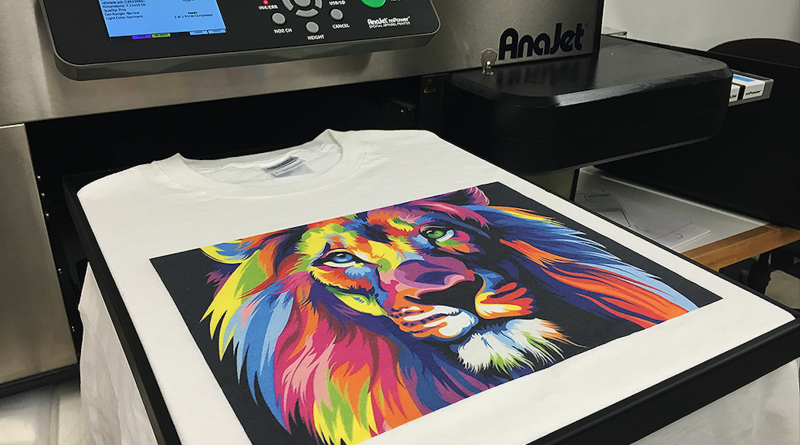

DTG printing is a new and innovative way to create high quality images on textiles. The abbreviation DTG stands for “direct to textile printing”. This method uses special printers that apply ink directly to the surface of the fabric, creating vibrant, detailed images. we provide Dtg printing services in Dallas lets discuss this printing method.

DTG printing offers unparalleled possibilities for creating customized and personalized products. It allows you to print on various types of textiles such as T-shirts, hoodies, polo shirts and other products. Because of this, DTG printing is extremely popular among designers and brand companies who are looking to offer unique products to their clients.

The DTG printing process involves several steps. First you need to download the image to your computer, where it will then be edited and prepared for printing. The appropriate printer and ink type are then selected that are most suitable for the selected textile materials. The image is then sent to the printer, which applies ink to the selected product according to preset settings. At the end of the process, the textile must be ingered to fix the image and ensure its durability.

What is DTG printing?

DTG printing (Direct To Garment) is a method of applying print directly to textile products such as T-shirts, polos, hoodies and others. She uses special equipment that allows her to print images and designs directly onto fabric.

DTG printing differs from other printing methods such as screen printing or heat transfer in that it produces high-quality, detailed images on textiles using a wide range of colors. This method is also more environmentally friendly as it does not require the use of many chemicals.

The DTG printing process begins with preparing the image on a computer using special software. The image is then transferred to a DTG printer, which applies it to the textile product. The printer uses special inks developed specifically for DTG printing, which penetrate the structure of the fabric and create a bright and durable image.

DTG printing is ideal for creating original and unique designs on textiles. It allows you to convey all the details and shades of the original image, while maintaining the brightness and saturation of colors. In addition, this technology allows you to print even one single item or small runs, making it ideal for custom orders and gifts.

Advantages of DTG printing:

- High quality and detailed images

- Wide range of colors and shades

- Ecological cleanliness

- Ability to print even one thing

- Ideal for custom orders

Overall, DTG printing is an innovative and effective method of printing textiles. It allows you to create unique and high-quality products that stand out from the rest. Due to its flexibility and superior quality, DTG printing is becoming increasingly popular in the textile industry.

Advantages of DTG printing

1. High quality printing: DTG printing provides high quality and clear images on textiles. It allows you to convey every detail and shade of color, making the printing on clothes realistic and bright.

2. Great Durability: DTG printing has excellent resistance to washing and color fading. The image will not peel off or lose saturation after repeated washing, which makes textiles with DTG printing very durable.

3. Endless design possibilities: DTG printing allows you to apply absolutely any image to textiles, including complex gradients and photographs. The absence of design restrictions opens up new opportunities for creating unique clothing.

4. Environmentally friendly: DTG printing does not use toxic dyes or chemical solvents, making it environmentally friendly. It also reduces waste during the printing process compared to other methods of printing images on fabric.

5. Flexibility and customization: DTG printing is ideal for producing small series or even one-off garments with unique designs. It allows you to create personal gifts, souvenirs or corporate clothing with an individual approach to each order.

Working principle of DTG printing

The DTG printing process begins with preparing the image on a computer. To do this, you need to convert the color image to the CMYK format, which allows you to create a wide color palette. The image is then loaded into the printer’s dedicated software.

DTG printing uses a special water-soluble four-color pigment ink that penetrates the fibers of the fabric. The printer’s print heads precisely distribute tiny drops of ink across the surface of the fabric, creating a color image.

One of the main features of DTG printing is the ability to apply high-definition details and high-quality color transitions, as well as print on dark and bright fabrics. This is achieved through the use of special preparation and fixing agents, which ensure high brightness and durability of the image on the fabric.

The benefits of DTG printing include the ability to print short runs, no need to create printing plates, and fast turnaround times. All this makes DTG printing a popular and effective method of applying images to clothing and textiles.

Features of choosing materials for DTG printing

When choosing materials for DTG printing, it is important to consider several factors that can affect the quality and durability of the print.

1. Fabric type:

DTG printing can be done on a variety of fabric types, including cotton, polyester, and blends of both. It is important to choose the fabric on which the print will look the highest quality and brightest. For example, for bright and rich printing, it is better to choose fabrics made from 100% cotton.

2. Fabric density:

One of the important fabric characteristics to consider when choosing materials for DTG printing is its density. On high-density fabrics, the print will appear sharper and more vibrant. The density of the fabric can also affect how the ink is applied to the surface.

3. Fabric color:

DTG printing can be performed on both light and dark fabrics. When printing on dark fabrics, you need to use special inks that provide bright and contrasting printing. When choosing materials for DTG printing, you should consider what color fabric will be used in order to select the appropriate ink and set up the printer.